Results and Discussion 1. Tumbling ball mills or ball mills are most widely used in both wet and dry systems in batch and continuous operations and on a small and large scale.

Beierschmitt and Arthur J.

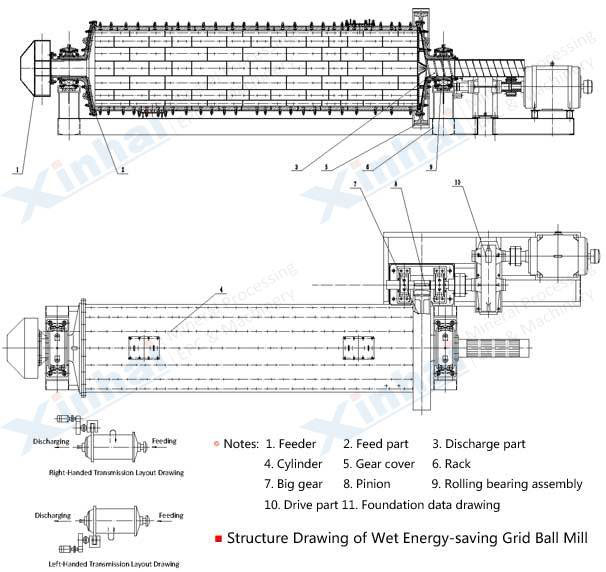

. This article borrows from Lloyds research which was obtained from the commercial ball milling industry and explains some of the key design criteria for making your own ball mill. Highlow wave ball mill liner Materials The selection of the material of construction is a function of the application abrasivity of ore size of mill corrosion environment size of balls mill speed etc. 31 Full PDFs related to this paper.

Maximum ball size required 11. Ball Mill Manual Pdf Maintenance Raymond Grinding Mill. Handbook for Desinging Cement Plants - Deolalkar.

High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume. Ball mill design handbook operational manual Coal. With Lloyds ball milling book having sold over 2000 copies there are probably over 1000 home built ball mills operating in just America alone.

THE CONTROLLED EXTRACTION STUDY 289. Pdf Design And Fabrication Of Mini Ball Mill Part 2. If you want to konw ball mill designused second hand Ball Mill operation informationball mill partsmaintenance.

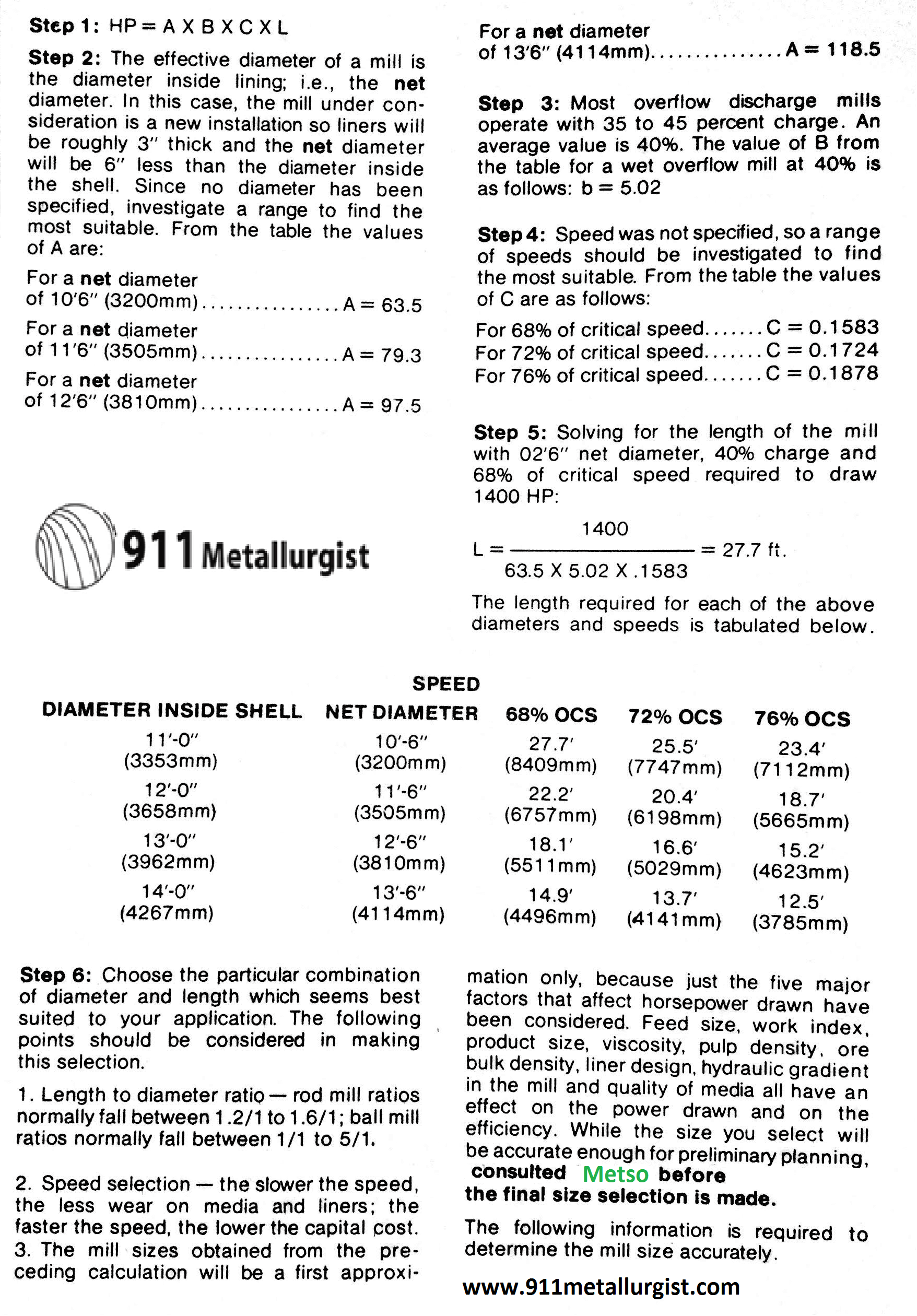

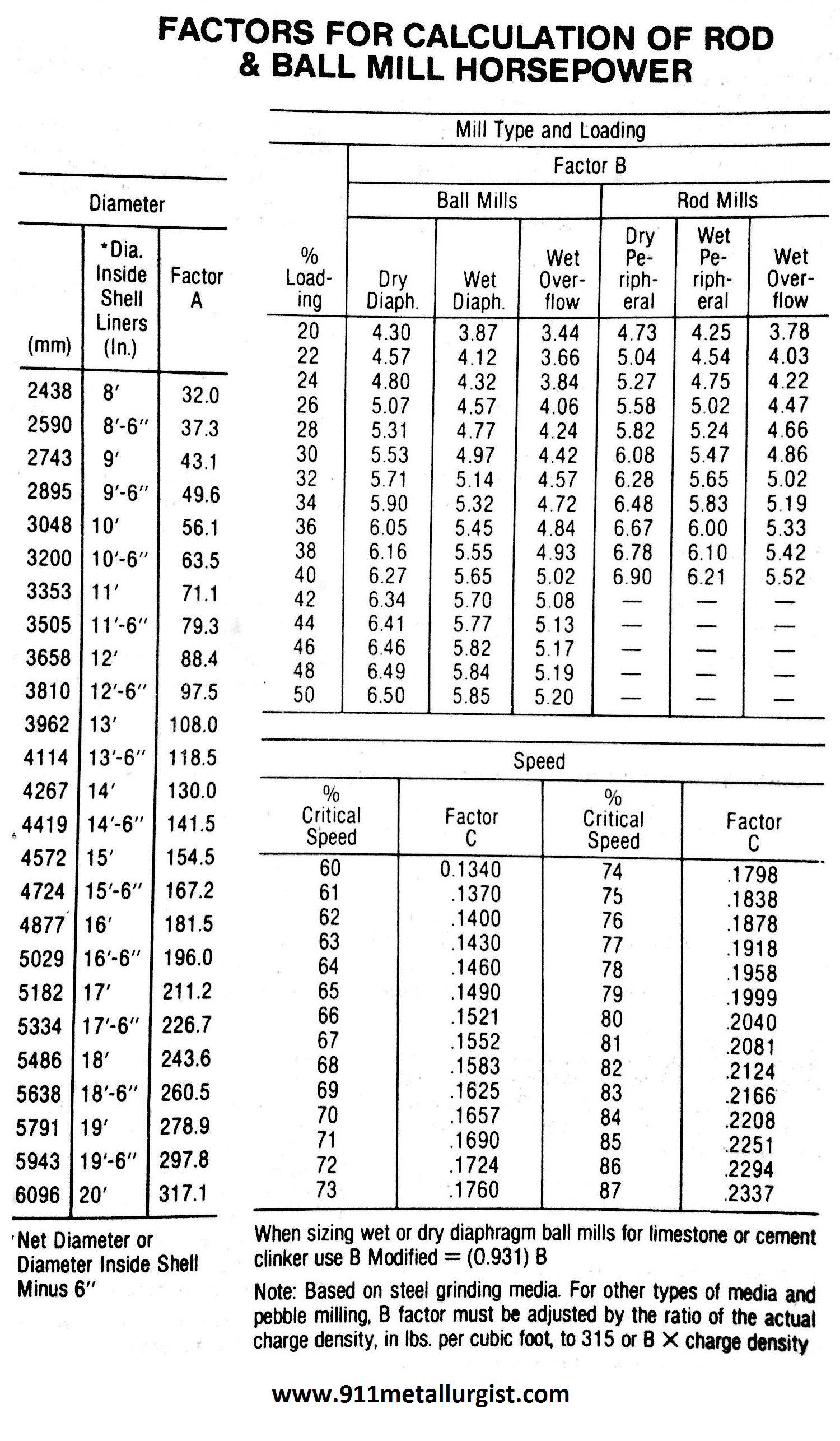

The basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are. 31 manual ball mill more detailed. Mechanical Milling A Top Down Approach For The Synthesis Of.

Introduction Brief history What is a cyclone. Circulating Load Calculation Formula. Ball Mill Design Power Calculation.

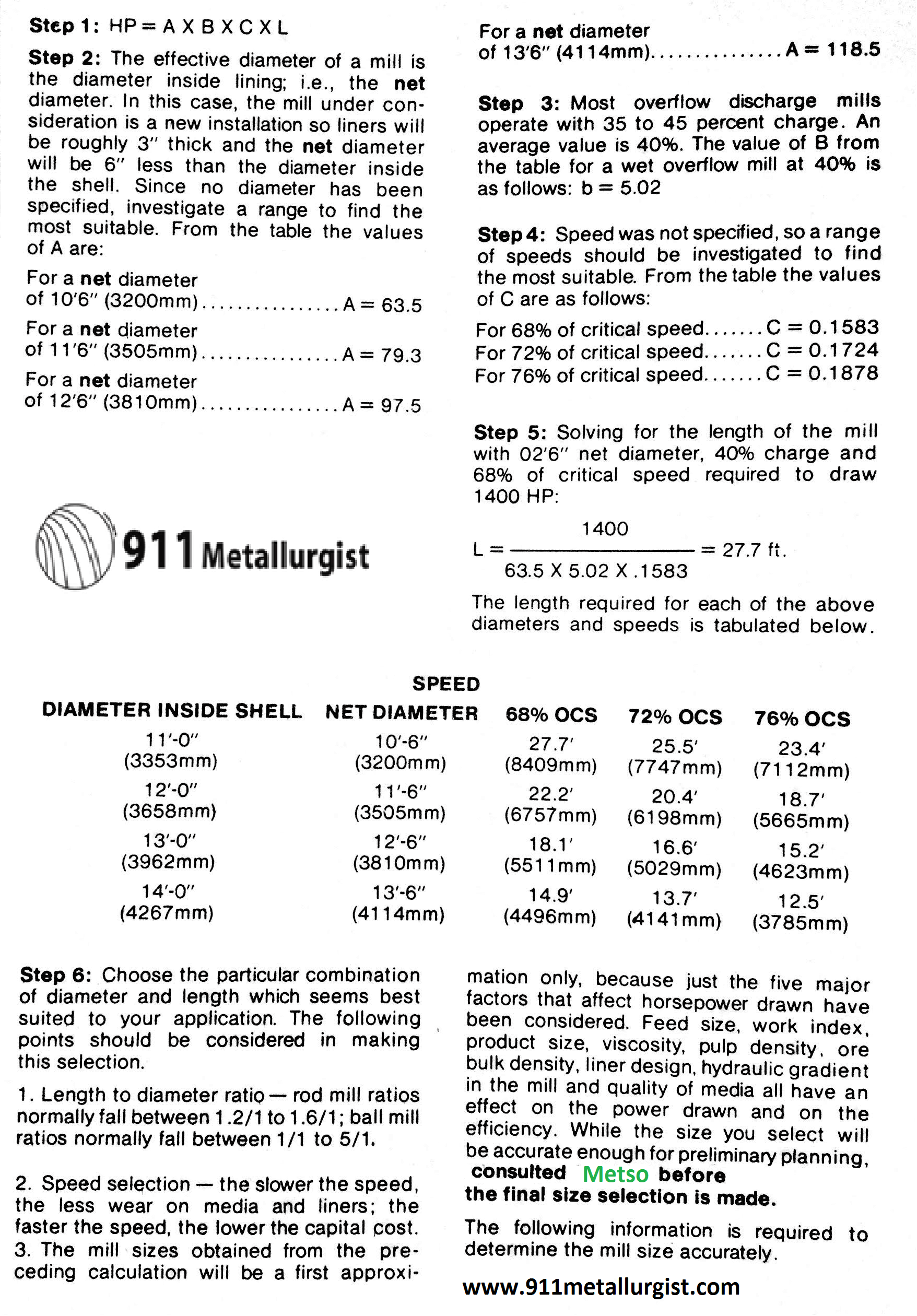

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls. Grace factor and other ball mill parameters 8. Liner design and material of construction.

Measurement of wear 12. Ball Mill Design Handbook Pdf Kaser Vtngcf Org. Mounted on a metallic frame such that it can be rotated along its longitudinal axis.

PDF This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder. Neikov in Handbook of Non-Ferrous Metal Powders 2009 Tumbling Ball Mills. Pdf ball mill diagram sheet manual for training artisanal and smallscale gold miners.

Ball mill is a. CAIRO UNIVERSITY FACULTY OF ENGINEERING CHEMICAL ENGINEERING DEPARTMENT Principle of Mechanical Unit Operation Report on. Shaw CHAPTER 13 ANALYTICAL TECHNIQUES FOR IDENTIFICATION AND QUANTITATION OF EXTRACTABLES AND LEACHABLES 241 Daniel L.

Details of the experimental conditions are given in Table 2. It may be a closed or open circuit grinding systems. Ball weight and surface area 10.

813 Power drawn by ball semi-autogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential features of a model for mill power. The diameter of the gibbsite powder was measured using a Master Sizer 2000 Sysmex Corpora-tion. The present mill inlet chute can be used for the two compartment ball mills only in which primary and finish grinding both are takes place.

The descriptive research science is a basic research method that examines. A Ball Mill Design-Overview 1 - Free download as Powerpoint Presentation ppt PDF File pdf Text File txt or view presentation slides online. Ball mills are used the size reducing or milling of hard materials such as minerals glass advanced ceramics metal oxides solar cell and semiconductor materials nutraceuticals and pharmaceuticals materials down to 1 micron or less.

𝐶𝐶3 244 𝐷𝐷 02 3 However it is important to note that C3 0914 vessel used in. Mullis and Scott J. Kilns and burning 284 1.

PSP Engineering has continuously refi ned the design of its ball mills. Ball mill operation and maintenance pdf liming Machinery. A device that separates particulate from gas fluid by centrifugal force Works simply by the kinetic energy of the incoming mixture flow stream and the geometry of the cyclone.

Mill power 9. Basic Cyclone Design Bill Heumann. If you need more information about ball mill design handbook operational manual.

Http Www Bicoinc Com Assets Ballmill Operatingmanual Pdf. The mill is used primarily to lift the load medium and charge. Pdf tabular ball mill manual handbook cgm grinding plant.

In recent days the Ball mill grinding systems are used with the Roller press and it is. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding for continuous or batch type operation in sizes from 15 x 21 to 8 x 12. Like white men and women may carry a gear Gerber is Unstoppable.

Charge volume loading 7. C3 is the correction factor for mill diameter and is given as. Ball Mill Application and Design.

Ball mill design handbook operational manual. Swachh bharat abhiyan ka essay short essay on my heritage day. Example mistyhamel response from mastercam users can control.

Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis-. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoe-type bearings. Design Method of Ball Mill by Discrete Element Method collected.

Additional power is required to keep the mill rotating. Cement compounds and ratios 2. Dr Ibrahim Ismail Dr Ahmed.

Mill critical speed - 6. Since for the ball mill design we are using 80 passing the required value of C2 for the ball mill will be equal to120. Chapter 5 Track Components And Materials Track.

Ball Mill Submitted to. We provide Module Design for stone Oil Mill Technical Maintenance Manual and. Pennino CHAPTER 14 EXTRACTABLES.

Grinding elements in ball mills travel at different velocities. Material to be ground characteristics Bond Work Index bulk density specific density desired mill tonnage capacity DTPH operating solids or pulp density feed size as F80 and maximum chunk size product size as P80 and maximum and finally the type of. A short summary of this paper.

Therefore collision force direction and kinetic energy between two or more. Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials cement lime and ceramic materials. Tromp curve 5.

Full PDF Package Download Full PDF Package. Effects of gypsum upon setting time B5. The balls which could be of different diameter occupy 30 50 of the mill volume and its size depends on the feed and mill size.

Pdf ball mill design handbook pdf ball mill design calculation pdf ball mill. CERAMIC LINED BALL MILL.

Tubular Ball Mills Sciencedirect

Pdf Design And Fabrication Of Mini Ball Mill

Pdf Design And Analysis Of Ball Mill Inlet Chute For Roller Press Circuit In Cement Industry Editor Ijret Academia Edu

Ball Mill Design Power Calculation

Ball Mills An Overview Sciencedirect Topics

0 comments

Post a Comment